torque values for fasteners continued...

3. Establish the

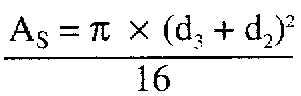

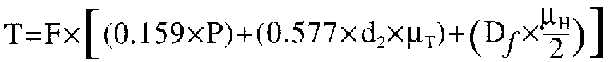

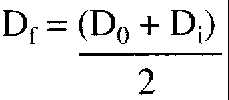

preload. The stress area of the thread As represents the effective section of the thread. It is based upon the mean of the thread pitch and minor diameters. It can be obtained from tables or calculated using the formula:  4. Determine the tightening torque. The relationship between tightening torque T and bolt preload F is:  If units of newtons and millimetres are being used, T will be in Nmm. To convert to Nm, divide the value by 1000. The effective friction diameter Df can be determined using the following formula:  For a standard hexagon headed nut, Do is usually taken as the across flats dimension and Di as the diameter of the bolt's clearance hole. Terms used in the formulae. T Tightening torque to be applied to the fastener. F The preload (or clamp force) in the fastener. sE Equivalent stress (combined tensile and torsional stress) in the bolt thread. A figure of 90% of the yield or proof stress of the fastener is usual. sT Tensile stress in the fastener. d2 Pitch diameter of the thread. d3 Minor (or root) diameter of the thread. P Pitch of the thread. mt Thread friction coefficient. mh Friction coefficient between the joint and nut face. Df The effective friction diameter of the bolt head or nut. Do Outside diameter of the nut bearing surface. Dj Inside diameter of the nut bearing surface. Care should be talsen to vse consistent units throughout. Note on the use of friction values As can be seen from tables 2 and 3, upper and lower limits to friction values are stated. Traditionally a mean value of friction is used when calculating the tightening torque and preload value. Be aware however, that for other conditions remaining constant, the higher the value of friction - higher is the required tightening torque and lower is the resulting preload. ____________________________________________________________________ Example calculation As an example, the above formulae will be used to determine the preload and tightening torque for a grade 8.8 M16 hexagon headed bolt. STEP 1. Establishing the dimensions and friction conditions. The data below is to be used d2 = 14.701 mm d3 = 13.546mm P = 2mm mt taken as 0.11 mh Taken as 0.16 STEP 2. Calculating the tensile stress in the fastener. Using 90% of 640N-mm2 gives sE= 576N/mm2, substituting values into the formula gives st= 491N/mm2. STEP 3. Taking the stress area As as 157mm2, gives the bolt preload F to be 77087N. STEP 4. Determination of the tightening torque T i) The effective friction diameter. Taking Do = 24mm and Dj= 17.27mm gives Df= 20.6mm. ii) Using the values calculated gives a tightening torque T of 223481Nmm, that is 223Nm. Contd..... |