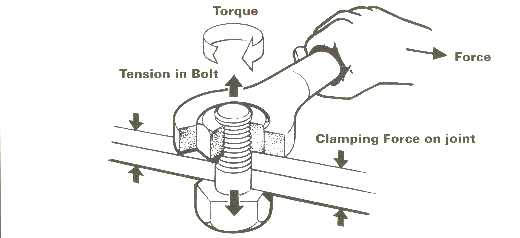

What is Torque? Torque is a 'turning' or 'twisting' force and differs from tension which is created by a straight pull. However, we use torque to create

tension.

Why? When a bolt is tensioned

correctly it is working at its optimum efficiency and will resist coming

undone. However, if the tension is too low the nut couid vibrate or work

loose. If the tension is too high (overstretched), the bolt could

break.

Referring to the diagram above it will be seen that Torque is the result of multiplying the value of Force applied by the Distance from the point of application. Comparing the two examples it will be noted that the same resultant Torque can be achieved with a lower Force if the Distance from the nut/bolt is increased It should also be realised that some torque wrenches are "length dependant" which means that the actual torque applied to the fastener varies if the hand position on the wrench is varied - even with the wrench preset! This occurs if the pivot point of the wrench mechanism is not coincidental with the point of application of torque. Note: Most Torqueleader wrenches are not length dependant.

|